LaserBridge

The LaserBridge System may be used together with one or more slave devices (a machine or device that is suitable to be placed under the bridge structure and that will define its cutting plane). A slave device may be one or more Embroidery Machines of any make or model.Our LaserBridge can cut directly on the embroidery frames and/or a fixed or motorized cutting Table and/or an Unrolling-Rolling system. The setup of our LaserBridge consists of a single version manufactured in different lengths so that it may be adapted to any Embroidery Machine or slave device.

The LaserBridge is designed to grow along with your business; thanks to an "Extension" you can add to increase the length of the bridge structure in order to add on further Embroidery Machines or other slave devices. The LaserBridge provides flexibility, reliability, accuracy and quality, all at a very competitive price.

LaserBridge is a CO2 Laser machine equipped with a 50, 100 or 200 Watt CO2 laser source with galvanometric laser beam movement system (galvanometer laser head). This kind of laser beam movement system allows for very high working speed and, in consequence, high productivity of laser cutting and laser engraving.

| WHAT YOU CAN ACHIEVE | VIDEO GALLERY |

| [huge_it_slider_id="2"] | [huge_it_slider_id="3"] |

MAIN FEATURES

- Usable with any Multihead Embroidery Machine, regardless of model or make.

- 600x600mm laser cutting-laser engraving area on each head of the Multihead Embroidery Machine.

- The device is totally PC controlled by means of a supplied interface card.

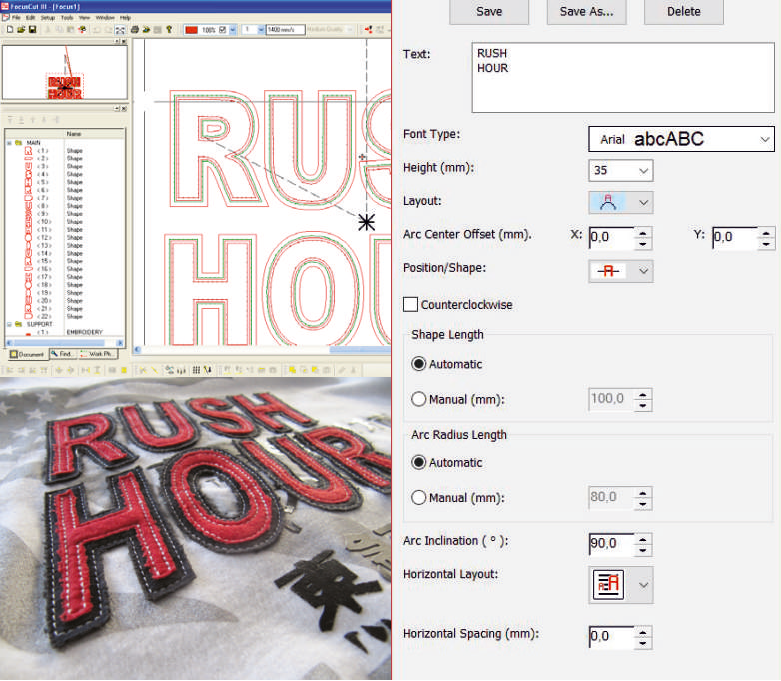

- Software for laser cutting with advanced features make work preparation easier as well as allowing for device customization.

- Laser cutting work parameters (power, speed, repetitions, etc.) independend for each shape to be cut/engraved in order to allow working several types of material on a same embroidery hoop of the Embroidery machine.

- Highly reliable and high-performance CO2 Laser source (air-cooled) + galvanometric head (scan head).

- External fume suction device easily connects to any filtering system.

- Reliable heavy duty motors and controls to ensure quality for the life of the machine.

- Extremely strong structure built to withstand the most vigorous production schedules.

- Innovative building solutions guarantee high working speed and performances without comparison.

- Innovative safety systems guarantee the workplace safety.

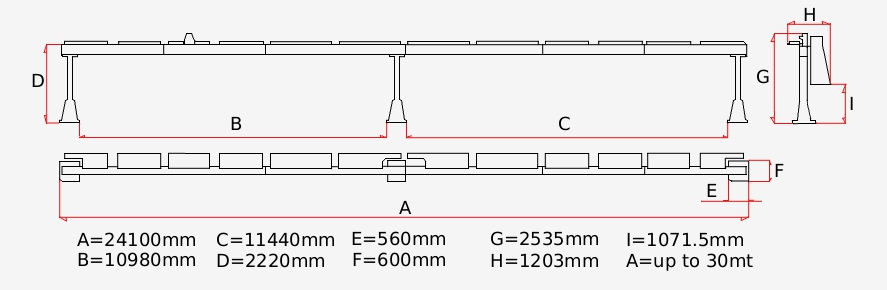

TECHNICAL SPECIFICATIONS

| Electrical input |

220/240 Vac ±10% - 50/60 Hz ±2%

|

| Absorbed power max. |

5300 W

|

| Dimensions |

see "LASERBRIDGE DIMENSIONS "

|

| Weight max. |

1500 Kg (10mt.)

|

| Noise emission |

<70 dB (without fumes suction unit)

|

| Drive motors type |

Brushless

|

| Working area (LxP) |

up to 600x600 mm (24"x24")

|

| Cutting plane size (LxP) |

defined by the slave device

|

| Cutting plane type |

defined by the slave device

|

| Fumes extraction |

suction hood

|

| Fumes suction |

external free standing unit

|

| Laser source type |

CO2 - 10.6µm sealed type - RF air or liquid cooled

|

| Laser power |

50 W / 100 W / 200 W

|

| Laser beam delivery |

Galvanometric scan head

|

| Laser spot diameter |

155 µm - 520 µm

|

| Cutting speed |

up to 10 m/s

|

| Translation speed |

1.7 m/s

|

| Acceleration |

5 m/s²

|

| Resolution |

5 µm

|

| User interface |

personal computer

machine control panel external keyboard RF transmitter |

| Languages |

EN / IT / FR / GE/ SP / PO

|

| Software |

FocusCut X - LaserBridge Manager

|

| Laser product class |

Class 1 (EN-60825-1:2003-02) - (USA-CDRH 21 CFR)

|

| Safeties |

protective enclosures + laser beam stop

protective laser safety scanner barrier red/orange flashers safety lateral bumpers |

The Manufacturer reserves the right to make modifications and improvements without prior warning

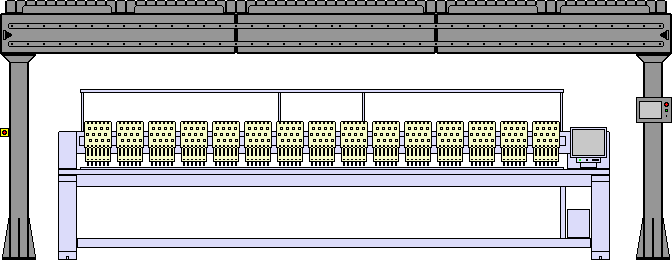

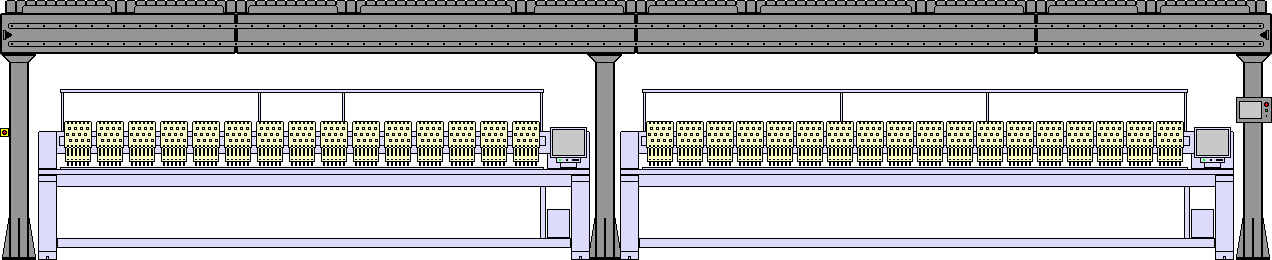

CONFIGURATIONS

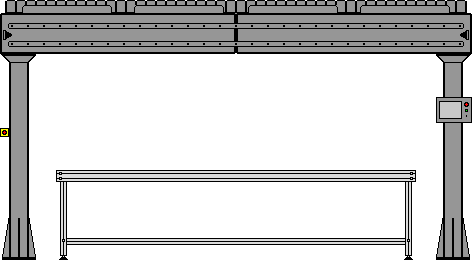

|

With one Embroidery Machine |

|

|

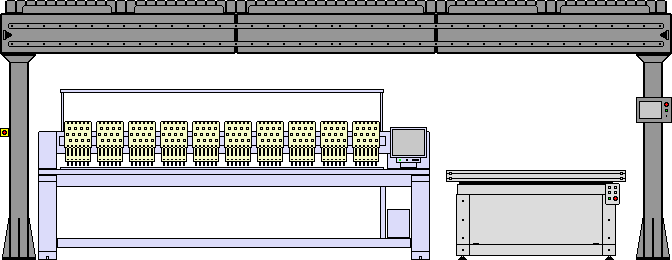

With more Embroidery Machines |

|

|

With more Embroidery Machines using the "Extension" |

|

|

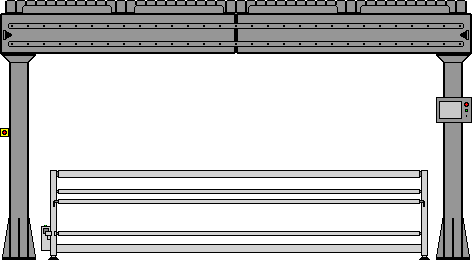

With a Cutting Table (fixed or motorized) |

|

|

With an Unrolling-Rolling System |

|

|

With an Embroidery Machine and a Cutting Table (fixed or motorized) |

|

|

With an Embroidery Machine and a Bridge Plotter System |

|

OPTIONS

Other Slave Devices

Over to one or more Embroidery Machine an other slave device may be a fixed or motorized Cutting Table (to cut pieces of material positioned on the table) and/or an Unrolling-Rolling system (to cut materials supplied in rolls)

New touch screen control panel with main controls and alarms list

Remote Control

The Transmitter allows to easily pre-program up to five files to be processed withe the Laserbridge in that way the operator of the Embroidery Machine only has to press the corresponding buton of the Transmitter in order to execute the desidered work witn the Laserbridge

New Feature Camera

Camera System can easly recognize outlines and give the command to the Laserbridge to cut/engrave on the sampling table or over the roll to roll machine

INSTALLATIONS

LASERBRIDGE has been installed and works with the most important marks of embroidery machines

A.I. LASER FUNCTIONS

| A.I. Laser Functions is a set of software tools powered by Artificial Intelligence algorithms that automizes the necessary operations to convert any traditional vector or embroidery file in a ready-to-use laser job.The operator can easily add laser operations to embroidered lettering, generate the cutting information on imported vectors files, use traditional embroidery files to get complete applique jobs or create any type of sequencial marking like serial numbers or barcodes starting from information stored on an external data source. Everything with just a mouse click |

|