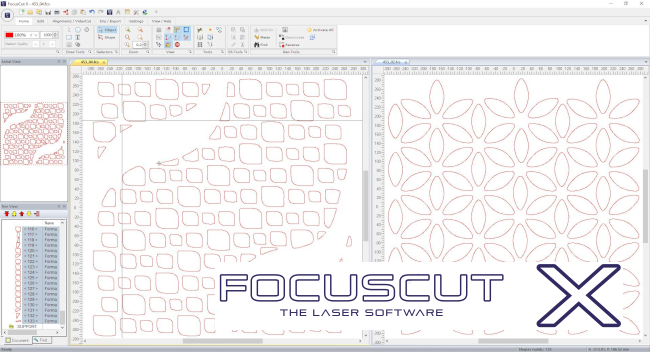

FocusCut X

Since 1977 we have developed software with the aim of providing our Customers with products that are complete and fully-developed, yet at the same time functional and easy to use. Over the years we have designed and produced many software programs dedicated to our Laser Machines. Our current range of products comprises the following software able to satisfy any production, economic or user need.

FocusCut X is a vector-based graphic software designed specifically for creating geometric figures. Use it to create texts, shapes, ornaments, boring-work, label and application edgings and artistic works requiring the cutting and engraving of different types of materials. FocusCut X allows the user to create desired artwork (*.fcs format) and then transmit it to any of Proel's Laser Cutting Machines (Galaxy, Galvanometric, LaserBridge systems etc...). If you purchased a model with a video camera, you may automate the cutting and engraving process by using Proel's VideoCut software (a seperate software program that can be integrated with Focuscut X) to perform the task of automatically recognizing the shapes or labels to be cut on the material being used.

THE FOCUSCUT VERSION DOWNLOAD IS AVAILABLE TO Download PAGE

General features

- Simple and rapid configuration of operating parameters

- Truly intuitive interfaces between user and work tools

- Management of six interface languages (Italian, English, German, French, Spanish, Portuguese)

- Display of the cutting plane of the machine on the work area

- Numerous display tools (zoom, show/hide, panoramic, grid...)

- Designed for WINDOWS 11, compatible with WINDOWS 10 or WINDOWS 8

File Management

- File management by the Archive with icon previews, use of search keys, import/export.

- Management of many graphic formats

- Importation of images from files, scanners or other peripherals with Twain standard

- Importation of different formats of embroidery files as images or as cutting files

- Importation of AI, DXF, DWG, EPS files

Drawing

- Simplified drawing of segments, sections, arcs, circles and open or closed geometric figures

- Modification of the drawn entity (rotation, redimensioning, transformation, mirror image...)

- Editing of the drawn entity (addition, transformation and deletion of nodes)

- Complete management of the imported images (resizing, rotation...)

- Automatic description of the outlines of the imported images (outline)

- Foto rastering (only for Galvanometric or Plotter Galvanometric Systems)

Work Management

- Assigning the desired cutting or engraving power to each entity drawn

- Repetition of the same cutting shape to define a matrix composition

- Automatic optimization of the cutting shapes

- Definition of the order of execution of the drawn shapes

- Execution of straight cuts to butt the material

- Manual control of the "stop" and "advance motorized cutting plane" functions

- Automatic management of cutting plane advancement

- Detailed summarized information on the work to be carried out